You are probably aware that the water problem in the Permian Basin is dire—it is the desert, after all. But the issue isn’t so seemingly obvious. Of course, as a natural resource, water is scarce in the Permian, and that is an issue that in itself places constraints on growth and development. But that is not the water problem we are talking about. It’s the produced water problem. Or better said, The Produced Water Challenge.

While the existence of produced water has been around as long as drilling has, the sheer volume of water needed—whether fresh or (recycled) produced water—has skyrocketed. Frac operations—especially since “the shale revolution”—require tremendous amounts of water. This leads to a bifurcated situation: what is the sustainability of current methodologies for disposal, and what are the infrastructures and processes in place to take a product once regarded as waste and turn it into an asset?

Jon Bessette sits atop a trailer housing the electrodialysis desalination system at the Brackish Groundwater National Desalination Research Facility (BGNDRF) in Almogordo, N.M. The system is connected to real groundwater, water tanks, and solar panels. Photo Credit: Shane Pratt:

While the first issue—sustainability—has bumped up against physical, regulatory, and economic limitations, the latter question comes down to the industry’s ability to come to market with technology that is economically feasible and addresses issues along the produced water chain. Fortunately, because of individuals like Steve Coffee, Raj Ghimire, Ben Samuels, Michael Grossman, and members of the board of The Produced Water Society, the industry is taking up the challenge. Leaders are working to unite stakeholders—including global majors and local environmentalists—in addressing the issues related to produced water (more at producedwatersociety.com). From new technologies that can be installed inside currently existing tanks and vessels to revolutionary electrochemical processes and ultra sensitive in-line sensors, there is no shortage of answers to the current Produced Water Challenge.

Disposal of produced water in the past was largely a matter of just pumping it back down underground, as is seen in the proliferation of SWDs (Salt Water Disposals) that dot the landscape in the Permian Basin. This process has now reached critical levels of either (A) reaching capacity, (B) encountering increased regulation because of induced seismicity (read: earthquakes), or (C) rising costs of disposal. The costs, which were rising even before the pandemic, have gone up yet more in the last few years. Clearly, there is no rug large enough for sweeping beneath it the 33,000 Olympic sized pools’ worth of water a day. Not even on eBay.

The Permian Basin alone produces approximately 15 millions of barrels of water a day. Through normal drilling, completions, and production, the numbers are staggering. Applying the standard rate of 44 gallons to the barrel, a total of 15 million barrels equals about 660,000,000 gallons of water a day. That’s your 33,000 backyard swimming pools of water. Each day. For perspective, the City of Midland uses on average approximately only 16 million gallons a day (363,636/bbls). If that water cannot be injected back into the disposal wells, where is it all going to go?

One “environmental” solution is to “put it back into the rivers” as has been suggested. Well, hold your literal and metaphorical horses. Ira Yates, president and Founder of Friends of the Pecos River (more at: friendsofthepecosriver.org) recently said during an interview, “Well, the water has to be clean. How clean is clean? Also, people generally don’t know how the natural system of a river is. And so just randomly putting water back into the river is not necessarily a good idea. There are consequences to that. If you put it into a salt creek, for instance, where one of the applicants currently is, it may bring more salt water down to the river and not less. There are reasons why you want to give more consideration to where you put the water.” Yates also stresses that municipalities and land owners need to be brought into the discussion as well. It is a good thing the discussions are being had now, because even in the best of scenarios, long term solutions need to be balanced between many stakeholders in a natural reuse scenario.

Ira Yates

Beneficial reuses’ time has come—and, as the name implies, it is taking what was once wastewater and, having treated it, returning it back to a beneficial reuse. Such reuse can come in the form of agriculture (non-edible crops), industrial (cooling), non-potable residential and commercial use, and even potentially drinking-grade water. This only scratches the surface of the myriad of uses for treated produced water. However, as astute observer Kent Shiller notes (see the accompanying quotation), we can get wastewater purified to municipal grade, drinking quality water—but at what cost?

And so enters a great wrinkle in the produced water industry that has some to mirror oil refining: water cleaned/refined just enough for its relative use. And that use can range from less-expensive, less treated water for one application, to a more highly purified result for another application at a greater cost. However one wants to slice the pipeline, there are almost no end of applications for the reuse of produced water.

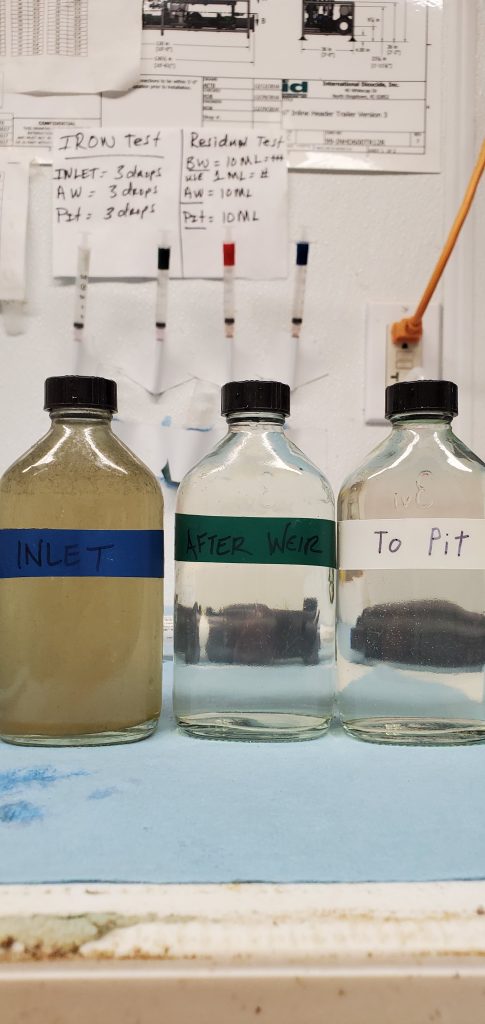

These samples show the progress of produced water through a chlorine dioxide treatment process in Andrews county. Photo Credit: Christian Lombardini

Some uses of produced water include reuse in frac operations, industrial cooling systems, and chemical manufacturing. Getting up to scale for non-food agriculture use (think textiles and industrial applications) is also a future option to relieve the use of fresh water, especially in challenged areas such as the Permian.

It took time for the marriage of critical need, advances in technology scaled to commercial application, and economical feasibility relative to the end use to occur. We are now at that tipping point between recognition of most of the major players of the critical urgency of the produced water opportunity. But more players are appearing every day, looking to capitalize on the Produced Water Challenge. The challenges to the future need to be answered today. One potential answer: Nuclear.

Water treatment, at scale, is an energy intensive process. One of the innovative solutions being explored by Natura Resources is using nuclear power to relieve pressure on the grid while potentially treating large amounts of produced water. Natura Resources, in conjunction with Abilene Christian University (ACU), Texas A&M University, The University of Texas at Austin, and The Georgia Institute of Technology, is building the first U.S. research nuclear reactor in over 30 years. That reactor is soon to debut at ACU (more at naturaresources.com). Desalination of water requires a lot of what is called “process heat,” and a nuclear reactor can produce generous amounts of that. With their reactor promising such a consistent source of thermal energy, Natura Resources is eager to see how these two sectors (nuclear/produced water) can complement one another.

In speaking with Tim Brown, Senior Mechanical Engineer at Natura Resources, I learned how dispatchable low carbon electricity production is perfectly suited towards nuclear. “Other well-known forms of low carbon electricity production, wind and solar, are not dispatchable. They are only available when the wind is blowing and the sun is shining. Nuclear is one of the few dispatchable technologies that meets the low carbon criteria. While there are other power sources to exploit—hydroelectric and geothermal, for example—those technologies can’t be utilized everywhere, but nuclear, theoretically, could.”

While potentially a few years away, the possibility of large (and small!) scale produced water treatment via nuclear power is not something the average Permian Basin rancher would have ever thought of 10 years ago.

Benjamin Judge

Benjamin Judge, Staff Engineer, Massachusetts Institute of Technology (MIT), on the Kira project (more at Kira.eco), is also looking to the future: he and a small team attended the Produced Water Society Conference in Houston, “to discover the challenges facing stakeholders in the oil and gas produced water space. Our goal was to network with and learn directly from experts, decision makers, and thought leaders as a springboard to focus our R&D efforts.” Indeed. When power hitters from MIT show an interest, be sure changes are afoot. Continues Judge: “We believe the merits of our technology is adaptive power conversion to flexibly treat water in remote and deployable scenarios where produced water is generated. We want to be part of the solution to bring beneficial reuse and the water positive future to the West Texas region and beyond.” Their novel electrochemical applications will almost certainly be part of the Produced Water Challenge Solution Mix.

There is no way in this short piece to fully explain how some of the best minds around the world are focused on the Produced Water Challenge. The technologies are there, the need is there, the water is there. The time has come for a new water revolution—and the Permian Basin, once again, is at the forefront of the change.

Christian Lombardini, a former field operator and manager, is now a communications and content consultant for oil & gas companies and creators. You can find Christian and his The Oilfield Leader Podcast on LinkedIn.

The post The Produced Water Challenge appeared first on Permian Basin Oil and Gas Magazine.

pboilandgasmagazine.com (Article Sourced Website)

#Produced #Water #Challenge