The back office is usually just that in the oil industry—back behind the scenes. It rarely makes headlines for great technological leaps. Nonetheless, it looks radically different than it did 10, even five years ago. Quietly, smartphone apps and the ability of accounting software to mine and analyze data from field monitoring systems have replaced paper forms, lost tickets and intermittent readings with smooth dataflow, real-time data, and real efficiencies.

Greg Archbald

Shortly after smartphones were invented, Greasebook began using them to shift pumper data from loose papers to those phones. Now, says the company’s founder and CEO Greg Archbald, Greasebook’s new app, Tiny Pumper, is helping small to medium companies move past the phone and into real-time data, on a budget.

And Enverus, known internationally for its research, also offers oil and gas accounting systems, including their own newest option, called RFx (Request For Anything).

Greasebook

Archbald indeed credits Steve Jobs and the iPhone with enabling the Greasebook system and with breaking down the oil patch’s historic resistance to new technology.

“I think Apple and Google fought some of the battles [of technology adoption] that, fortunately, we didn’t have to fight.” He added that today, almost nobody, regardless of age, ventures forth without their smart phone. That makes the adoption of this mobile-based technology very easy.

He explained, “Greasebook is a simple mobile app that a pumper would download to their iPhone, Android, tablet, or laptop—anywhere they want to run it. It essentially enables the pumper to communicate all their run tickets, gauges, gas measurements, commentary, history files—anything that anybody anywhere on the team would want to know about an oil and gas asset. They put it right into their phone,” he said.

Once the data is collected, the system immediately makes it available to anyone on the team who needs it, anywhere in the world.

Greasebook’s hardware and software are designed to be labor-savers.

Its ability to take this data out of file cabinets, hard drives, and clipboards actually helped Greasebook thrive during the COVID shutdowns, Archbald recalled, because “everybody was working outside the office, from home” and accessing that data online was sometimes the only option.

“We were already set up for that,” he says. That’s because, while the company is based in Oklahoma City, it already had clients collecting data across the United States. The shutdowns “really provided the impetus for a lot of operators to get on track with a simple solution that was lightweight, easy, and cost-effective for them to run,” he said.

Tiny Pumper in My Hand

While Greasebook’s data integrated with other office software, Archbald said his clients, who are mostly small-to-medium companies, began telling him they were happy with what the system already did for them—and they wanted a new level.

The alone data was great, but it still relied on pumpers driving to the site to collect data on the pumper’s schedule. Customers wanted Greasebook to move up a notch, providing “more granular data, more timely data,” from the field.

Tiny Pumper allows end users to attach a sensor to various kinds of field equipment and begin receiving data quickly. Archbald said, “It’s hardware you can literally have set up and running with hourly updates in less than 10 minutes.

Further development of the electronics involved has enabled this addition as well. “What we’ve done is to take all the components from a smartphone [and] we’ve combined them into a really slick, simple piece of hardware that somebody, if they can screw in a lightbulb, can use. Tiny Pumper. So Greasebook has turned into an entire ecosystem.”

For Archbald’s target market of independent producers, traditional SCADA systems tended to be too expensive and too complicated. With Tiny Pumper, his goal was to provide those companies with “99 percent of that utility for less than 5 percent of the cost, and to be installed in less time than it takes you to tie your shoe,” he said.

This ease of use also allows companies that may be short on staff to use one pumper to handle the work previously spread among several. “Now you can double down on your A+ pumpers and maybe give them a bonus,” he suggested.

After about two years of testing and refining, he said, they began to release the product to the field in 2024, with very positive feedback.

Living up to its name, Tiny Pumper, a Greasebook product, is visible in these images.

Enverus and More Innovation

Enverus is another company adding and refining services in response to the needs of clients and industry. The company’s VP / Product Management, Ian Elchitz, said that digitization is playing a critical role in addressing industry challenges of achieving “more efficient, scalable, and cost-effective operations” with fewer resources due to staff shortages and downsizing.

Some examples include:

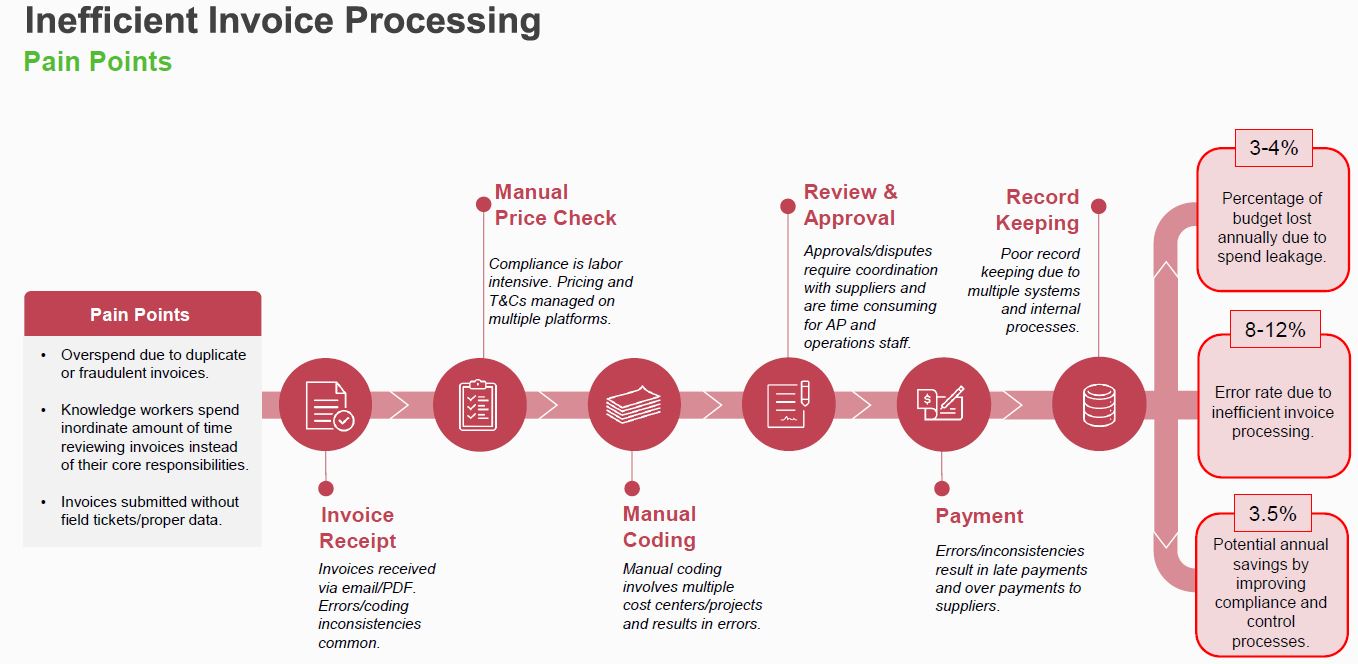

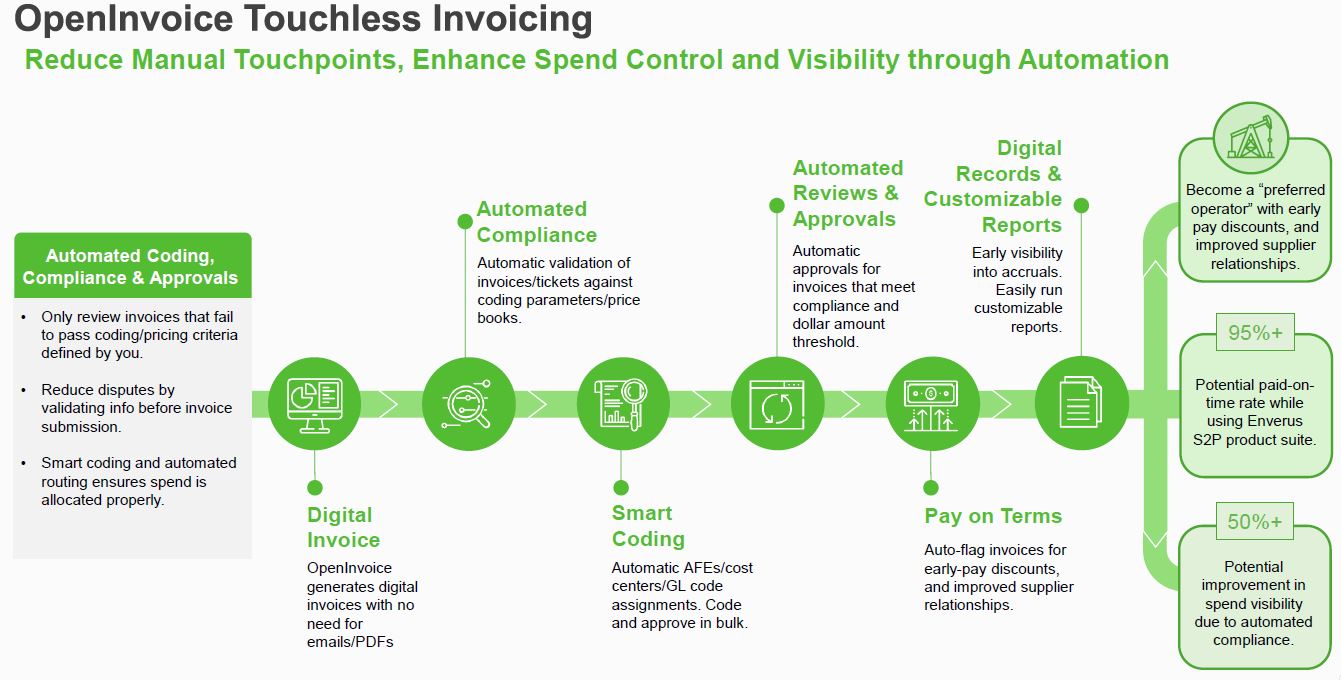

* Automating Routine Tasks. Digitizing repetitive tasks such as invoice processing, field ticket validation, and contract management can at the same time reduce the work required of staff and increase accuracy.

* Upscaling Without Added Staff. As work volumes grow, companies are looking to digital tools to scale up (or down) without hiring. “This is especially valuable in high-transaction environments like the Permian Basin,” Elchitz observed.

* Data-Driven Decision Making. By centralizing data, digitalization offers actionable insights, which allows smaller teams to make faster, more informed decisions.

* Streamlined Collaboration. Aggregating of data into digital platforms improves inter-departmental communications, which lets teams collaborate and better understand the big picture.

Elchitz sees AI and machine learning as transformational in such routine operations as reconciliation and anomaly detection, “while providing predictive insights to enhance decision-making. Integration is increasingly important as businesses prioritize seamless workflows that connect accounting systems with procurement, CRM, and other enterprise tools.”

“Request for Anything” Tool

As an example of how technology enables data-driven decision making, Elchitz offered Enverus’s newest system, RFx (Request for Anything), which was previously known as BidOut. It enhances “both strategic and tactical sourcing capabilities,” he said, adding that it addresses “critical procurement needs” in order to “fully cover the source-to-pay lifecycle.”

Here are some of its uses in sourcing strategies: It helps manage large, multi-vendor RFx processes efficiently, which allows operators to compare bids side-by-side and select the best option.

Ian Elchitz

If offers insights into “market trends, supplier performance, and pricing benchmarks, which enhances negotiation power and improves long-term sourcing strategies.”

By streamlining the evaluation and selection process, it can optimize supplier relationships, which, Elchitz said “ultimately [creates] stronger, more reliable supply chains.”

He said RFx smooths day-to-day procurement in these ways:

* It simplifies tasks like “three bids and a buy,” streamlining the process of gathering competitive bids and finalizing purchases.

*It automates routine tasks so humans can focus on the higher-value processes of decision making, while assuring that the procurement tasks are done on time.

*And because it standardizes bid evaluations, it helps “ensure adherence to organizational policies and contractual requirements,” said Elchitz.

It also integrates with other Enverus software to help complete what he called the aforementioned source-to-pay process, “creating and end-to-end solution for procurement and payment workflows.”

The Big Picture on Digitalization

“The shift toward digitalization is driving faster adoption of advanced tools across the energy sector,” said Elchitz, “as companies recognize their necessity in bridging gaps caused by staffing constraints. With digital tools handling routine processes, companies can reallocate their workforce to focus on strategic, high-value tasks, such as operational planning and supplier engagement. Digitalization also ensures companies can maintain continuity and meet their goals, even during periods of rapid change or workforce limitations.”

Digitalization can also add flexibility—and it requires top-tier security, said Elchitz. “Additionally, user-friendly, customizable interfaces are becoming essential as more organizations seek solutions tailored to their specific needs. Cybersecurity and data privacy remain critical, with providers investing heavily in robust defenses to protect sensitive financial information.”

Industry is More Friendly

As noted by Archbald, Elchitz said the Permian is becoming more open to digital solutions. “While most large operators have long moved past the days of manual, paper-based methods, some medium-sized and smaller firms still grapple with outdated practices.” But more companies are realizing the risks of data loss inherent in those older systems and are looking to outsource the digitalization of their processes to a company like Enverus.

Overall, as both Archbald and Elchitz observed, the general adoption of technology across the board, combined with the necessity of streamlining and efficiency, are combining to increasingly release the industry’s death-grip on “this has always worked before.” Because, in truth, many of those ways didn’t actually work, they were just familiar. And now that’s becoming apparent as new advances continue to show.

Paul Wiseman is a longtime writer in the energy industry.

The post Office Functions: There is a Better Way appeared first on Permian Basin Oil and Gas Magazine.

pboilandgasmagazine.com (Article Sourced Website)

#Office #Functions